About Us

Who We Are

Polycarbonate is a high-performance tough, amorphous and transparent thermoplastic polymer with organic functional groups linked together by carbonate groups (–O–(C=O)–O–) and offers a unique combination of properties. PC is popularly used as an engineering plastic owing to its unique features that include:

- High impact strength

- High dimensional stability

- Good electrical properties amongst others

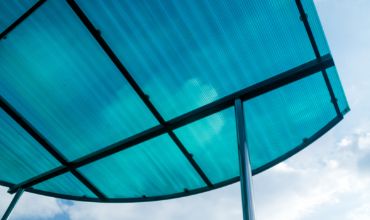

Though the characteristics of polycarbonate are similar to polymethyl methacrylate (PMMA, acrylic), but polycarbonate is stronger, usable in a wider temperature range (Melting point: 155°C) but more expensive. As PC shows excellent compatibility with certain polymers, it is widely used in blends, such as PC/ABS, PC/ PET, PC/PMMA. Some of the common applications are compact disc, safety helmets, bullet-proof glass, car headlamp lenses, baby feeding bottles, roofing and glazing etc.

Why Polycarbonate

PC is an ideal material well known and widely used in the industry for its versatile characteristics, eco-friendly processing and recyclability. Comprising a unique set of chemical and physical properties makes it suitable over glass, PMMA and PE.

Toughness and High Impact Strength

Polycarbonate has high strength making it resistant to impact and fracture, and further providing safety and comfort in applications that demand high reliability and performance.

Transmittance

PC is an extremely clear plastic that can transmit over 90% of light as good as glass. Polycarbonate sheets are available in a wide range of shades that can be customized depending on an end-user application.

Lightweight

This feature allows virtually unlimited possibilities to OEMs to design as compared with glass. The property also allows to increase efficiency, make installation process easier and reduce overall transportation costs.

Protection from UV Radiations

Polycarbonates can be designed to block ultraviolet radiation and provide 100% protection from harmful UV rays.

Optical Nature

For having amorphous structure, PC offers excellent optical properties. The refractive index of clear polycarbonate is 1.584.

How clear is polycarbonate?

While polycarbonate is valued for its strength and impact resistance, it is its transparency which allows it to take on a variety of applications and purposes than other materials cannot.

Polycarbonate sheets are significantly lighter than glass sheets of the same size and polycarbonate sheets also come with UV protective filters. Its durability and transparency make it an excellent alternative to glass.

How easy is it to work with polycarbonate? Thanks to polycarbonate’s outstanding impact resistance and light weight, working with it is fairly easy. Polycarbonate is easy to cut and fix with screws, nuts and bolts. And can be made into many shapes and sizes by thermoforming, cold curving or machining.

It can typically be formed at room temperature without cracking or breaking, similar to sheet metal. Polycarbonate is classified as a thermoplastic and this name has to do with the way polycarbonate responds to heat.

Thermoplastic materials become liquid at their melting point which is 155 degrees Celsius for polycarbonate.

After heating to melting point, thermoplastics, including polycarbonate, can be cooled and reheated again without significant degradation. In this way polycarbonate, can be easily injection molded and recycled. Polycarbonate offers fantastic heat resistance, dimensional stability, shock resistance and resistance to humidity. It stays stable in demanding temperatures and applications where other materials cannot be used. Polycarbonate’s high expansion is extremely important for the correct sizing of the sheets so if you would like any advice about using polycarbonate, do let our friendly plastic experts help you out.

Are there different types of polycarbonate?

Polycarbonate is produced in different grades (and prices) by several polycarbonate manufacturers. The common brands are Makrolon, Palsun, Lexan and Marlon.

A key consideration choosing polycarbonate is your end use. Standard polycarbonate may be adequate for some uses but where exposure to sunlight will occur or scratch resistance is important. But other grades will provide better longer term purpose. If using polycarbonate outdoors in direct sunlight a protected polycarbonate sheet is a better long term option. With UV protection included, protected polycarbonate resistsyellowing and de-colouring.

Polycarbonate sheets are also available with a hard coating applied to give a harder finish and improve their scratch resistance. Polycarbonate mirror is also available which delivers the mirroring of glass with superior properties such as significantly stronger impact strength, resistance to heat and dimensional and UV stability.

Solid polycarbonate sheets are often used instead of glass but, for roofing, a popular choice is twin wall and multi wall polycarbonate. These types of polycarbonate offer additional insulating properties.