Polycarbonate Kenya

and is a popular choice for carports, conservatories and patio coverings

Welcome to Polycarbonates Kenya

Where We Build Your Visions

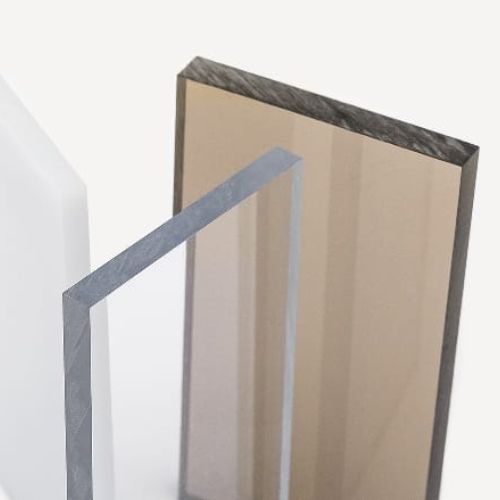

PC is an ideal material well known and widely used in the industry for its versatile characteristics, eco-friendly processing and recyclability. Comprising a unique set of chemical and physical properties makes it suitable over glass, PMMA and PE. Polycarbonates excellent transparency with UV filter and durability are valuable for making shatter-proof glazing and eye glasses: polycarbonate enables lens to be thinner than if they were made from glass.

Polycarbonate is an excellent choice for applications where sheet metal lacks viability, namely when transparency is needed and when a non- conductive material with good electrical insulation is a requirement.

Polycarbonate Price(PER PIECE)

| Hollow Polycarbonate Sheets | Ksh 14000 |

| Solid Polycarbonates Sheets | Ksh 40000 |

ACCESSORIES

| H Connectors | Ksh 2500 |

| U Connectors | Ksh 2500 |

Get Your Free Consultation

Polycarbonate makes an excellent material for tackling DIY jobs such as secure glazing and replacing greenhouse glass to make greenhouses virtually unbreakable year after year.

Our Products

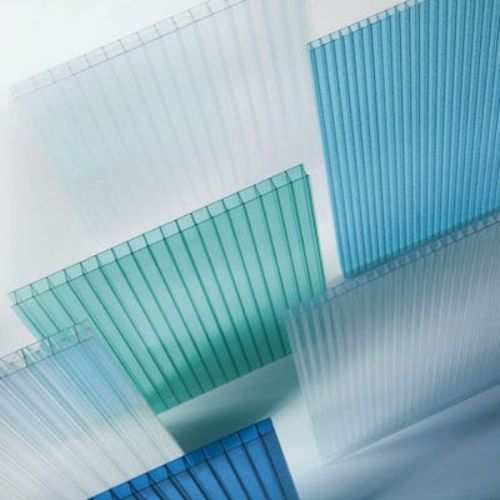

Hollow Polycarbonate sheets

Solid polycarbonate sheets

h connectors

u connectors

Our Recent Projects

Some of Our Projects include …

Successful Project

Polycarbonate Project

Project

What is polycarbonate used for?

Polycarbonate plastic is used by manufacturers, business and DIYers for many different purposes. Businesses and manufacturers make different products using polycarbonate. For example, its high strength and light weight are valued for making CDs, DVDs, mobile phones and laptops; using polycarbonate to manufacture these products means they can be incredibly light yet virtually impossible to break.

Polycarbonates excellent transparency with UV filter and durability are valuable for making shatter-proof glazing and eye glasses: polycarbonate enables lens to be thinner than if they were made from glass. Polycarbonate is an excellent choice for applications where sheet metal lacks viability, namely when transparency is needed and when a non- conductive material with good electrical insulation is a requirement.

Polycarbonate makes an excellent material for tackling DIY jobs such as secure glazing and replacing greenhouse glass to make greenhouses virtually unbreakable year after year. Polycarbonate glazed greenhouse Polycarbonate makes unbreakable greenhouse polycarbonate glazing makes greenhouses virtually unbreakable.

Polycarbonate is also a great solution where durable, rigid roofing is required and is a popular choice for carports, conservatories and patio coverings because it lets in the same amount of natural light as glass does whilst not being fragile. Polycarbonate patio cover makes great carport Opal Polycarbonate shades patio

How to Join Polycarbonate Sheets

Polycarbonate sheets can be glued together at home in 2 ways. Before you begin make sure your polycarbonate sheets are nice and clean – just rinse them in lukewarm soapy water and wipe in the direction of the grain with a soft cotton / gentle cloth. Dry the polycarbonate off with another soft cotton / gentle cloth.

There are two ways to bond polycarbonate sheets:

- Glue – polycarbonate sheets can be joined together with an epoxide glue. It is easy, just like gluing two materials together. Please note you will need to use an epoxide glue: if you use regular glues or solvents your polycarbonate sheets will appear to have tiny little cracks all over the surface and underneath the polycarbonate. You won’t be able to feel these cracks and the polycarbonate will remain strong but aesthetically not the clear polycarbonate you bought

- Fusing with methylene chloride – which gives a superior, seamless result and stronger bond (please do this in a ventilated area though as methylene chloride is toxic). Apply your methylene chloride along the edge of your polycarbonate sheet. Go for a small amount and give it a moment to soak into your polycarbonate sheet. When it feels slightly sticky place this edge onto the surface of the other polycarbonate sheet where you would like it to fuse. Press your two polycarbonate sheets so that they stay in constant contact to get a strong bond. When they can support themselves, leave them to dry for at least 48 hours. Do not put anything onto your polycarbonate during this time as it might damage the bond

Further Help

If you have any further questions about polycarbonate or require help with a project do let our friendly customer service team know. They will be happy to help.